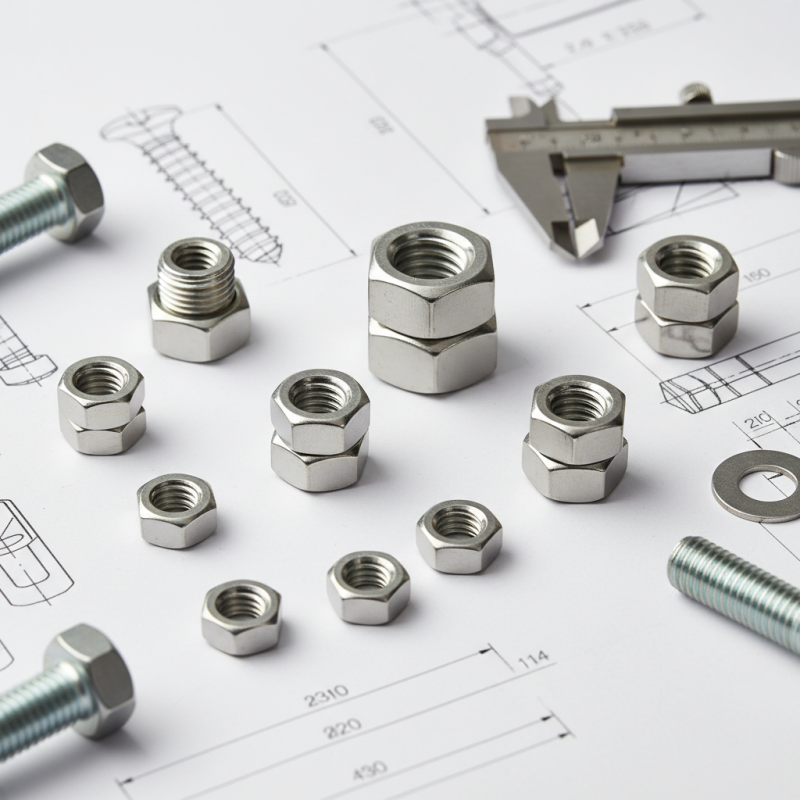

How to Choose Stainless Hex Nuts for Your Projects?

Choosing the right Stainless Hex Nuts is crucial for any project. These fasteners play a vital role in the integrity of structures and machines. According to the Global Fasteners Market report, the demand for stainless steel fasteners is projected to reach $40 billion by 2025. This highlights the industry's rapid growth and the necessity for quality choice.

Stainless hex nuts, known for their corrosion resistance and durability, are widely used in various applications. It’s important to consider factors such as material grade and thread type when selecting these components. Missteps in choosing the right stainless hex nuts can lead to project failures. It’s said that 30% of fastener failures stem from improper selection.

Paying attention to details is essential. For instance, the choice between standard and metric sizes can significantly impact your project's outcome. Recognizing that not all stainless hex nuts are created equal allows for better decision-making. The right choice can enhance performance, while the wrong one can result in costly errors. Always analyze specifications and conduct research to ensure reliability.

Understanding Different Types of Stainless Hex Nuts Available in the Market

Stainless hex nuts come in various types, each suited for different applications. The most common types are grades 304 and 316. Grade 304 is popular due to its good corrosion resistance. It's ideal for general use in dry environments. However, it may not perform well in coastal areas. The salt in the air can cause corrosion over time.

Grade 316 hex nuts offer enhanced protection against corrosion. They contain molybdenum, making them excellent for marine projects. This type is often more expensive, but worth the investment in harsh conditions. It's essential to understand the application before making a choice. Factors like temperature, exposure, and load bearing come into play. Mistakes in selection can lead to project failures. Trying to cut costs by using lower grades can result in structural issues.

When choosing hex nuts, consider the finish as well. Some come with plain finishes, while others are treated for extra resistance. However, finishes can add complexity to maintenance. It’s not always clear which finish is best for your needs. Reflect on your specific project requirements to make the right decision.

Identifying the Right Material Grade for Your Specific Project Requirements

Choosing the right material grade for stainless hex nuts is crucial for project success. Different grades offer unique properties. Common stainless steel grades include 304 and 316. Grade 304 is versatile, offering good corrosion resistance. It works well in many environments. However, it lacks resistance to saltwater and chlorides.

Grade 316 is better for harsh conditions. It contains molybdenum, improving its resistance to corrosion. This makes it suitable for marine and chemical applications. Consider the environment where the nuts will be used. Analyze factors like temperature and exposure to chemicals. A misstep can lead to premature failure.

It's also wise to assess the load and stress conditions. Some projects require stronger materials. Yet, not all projects need the highest grade. Sometimes, choosing a lower grade might be sufficient. It can save costs and still meet requirements. Reflecting on these choices can lead to better project outcomes.

Assessing Size and Thread Specifications for Optimal Fit and Performance

Choosing the right stainless hex nuts is crucial for ensuring the integrity of your projects. Size and thread specifications play a pivotal role in achieving optimal fit and performance. According to industry reports, a significant percentage of hardware failures arise from mismatched thread types or sizes. For instance, using a nut that is too small can lead to stripped threads and a compromised structure.

When assessing size, refer to standard measurements like diameter and height. It's essential to consider the corresponding bolt size. A hex nut should match the bolt's diameter precisely. Research indicates that a mismatch in diameters can reduce the load-bearing capacity by 30%. Thread specifications, including pitch and type, affect compatibility as well. Coarse threads may work better for quick assembly, but fine threads offer greater tension capabilities. Yet, fine threads can also be more prone to stripping in some applications.

One must also reflect on material properties. Stainless steel offers excellent corrosion resistance but can be brittle if not specified well. Not every project needs high-grade stainless steel. Often, a grade 304 may suffice, while in corrosive environments, opting for grade 316 is essential. Therefore, always assess the environment and load requirements before finalizing your choice. Such considerations lead to stronger, more reliable assemblies.

Evaluating Coatings and Finishes for Enhanced Durability and Resistance

When selecting stainless hex nuts, coatings and finishes play a crucial role in durability. Different projects have varying environmental conditions that can impact metal components. For example, outdoor installations may be exposed to moisture and salt, making protective finishes essential. A simple layer of protective coating can significantly enhance resistance to corrosion.

Some coatings provide a sleek finish, while others focus on strength. Polyurethane or epoxy coatings are popular choices. They create a barrier against harsh substances. However, not all finishes are suitable for every application. It’s vital to assess the specific needs of your project.

Inadequate protection can lead to quick degradation. This can be frustrating, especially when parts fail prematurely. Choosing a finish requires careful consideration and sometimes even experimentation. Look for specifications that match the demands of your project. Take the time to understand the requirements fully. This investment in detail will pay off in the long run.

Considering Application Contexts and Load Requirements for Hex Nuts Selection

Choosing the right stainless hex nuts for your projects is crucial. The application context impacts the type of nut you need. For instance, in high-stress situations like machinery, you'll require nuts designed to withstand greater loads. Weight and tension play vital roles in determining strength.

Consider the environment where these nuts will be used. Moisture and chemicals can corrode standard metals. Stainless steel can resist corrosion, but not all grades are equal. The wrong choice might lead to rust or structural failure.

**Tips:** Ensure you check the specifications of your application. Calculate the load requirements carefully. Testing prototypes can reveal potential issues before full-scale production.

In some cases, over-engineering can result in overspending. Not every project needs the highest grade stainless steel. Reflect on your needs. Finding a balance between cost and quality is ideal. Small adjustments can save you money and time.

How to Choose Stainless Hex Nuts for Your Projects? - Considering Application Contexts and Load Requirements for Hex Nuts Selection

| Application Context | Load Requirement (lbs) | Recommended Material | Nut Size (Hex Width) | Finish Type |

|---|---|---|---|---|

| Mechanical Equipment | 500 | Stainless Steel 304 | 3/4 inch | Plain |

| Outdoor Structures | 300 | Stainless Steel 316 | 1 inch | Hot Dip Galvanized |

| Automotive Applications | 400 | Stainless Steel 410 | 1/2 inch | Nickel Plated |

| Marine Applications | 600 | Stainless Steel 316L | 7/8 inch | Polished |

| Construction Applications | 800 | Stainless Steel 303 | 1.5 inch | Black Oxide |